The Ultimate Guide to Industrial Bag Filters: How to Choose the Right Dust Collection System for Your Factory in 2025

Are You Facing These Dust Removal Challenges?

- ❌ Do filter bags rupture often? Do annual replacement costs exceed $50,000?

- ❌ Have environmental authorities penalized you for exceeding dust emission limits?

- ❌ Is your energy consumption high due to excessive system pressure drop?

Industrial operations are vital to our modern world. But they often create large amounts of dust and particulate matter. Controlling these emissions is very important. It helps meet strict environmental rules, like the EPA’s PM2.5 standards or China’s GB 4915-2024 for cement plants. It also protects worker health, ensures equipment lasts longer, and keeps production efficient. Industrial bag filters, also called baghouses, are among the most effective tools for this.

But choosing the right bag filter solution is not easy. It needs deep technical knowledge. You must carefully consider specific operating conditions. Expertise in system design is also key. This is where Jiangsu Guantong Shengshi Intelligent Technology Co., Ltd. (Guantong Shengshi) helps. We have over ten years of experience in environmental protection engineering. We specialize in advanced, reliable, and custom bag filter solutions for demanding global industries.

This guide uses Guantong’s wide expertise. It will walk you through the key factors in choosing an industrial bag filter system. This system will meet compliance and also optimize your operational efficiency.

1. Guantong’s 5 Breakthrough Technologies in Intelligent Bag Filter Systems

Technology 1: Dynamic Differential Pressure Cleaning Control System

- It Solves This Pain Point: Traditional timer-based cleaning causes excessive wear and wastes energy. Our system stops this.

- Technical Highlight: Real-time differential pressure sensors control pulse-jet cleaning. These sensors are accurate to ±5Pa. For cement plants with high dust loads (over 50g/Nm³), pulse cycles can be set for every 15 minutes. For low-dust chemical uses (under 5g/Nm³), our smart system can automatically extend cleaning to every 4 hours. This saves 23% in energy compared to normal units.

- Case Data: This system reduced annual maintenance costs by 63% at a major steel plant.

Technology 2: Patented Cone-Shaped Bag Structure for Sticky Dust

- It Solves This Pain Point: This design helps with poor dust cake release and blockages from sticky particulates.

- Technical Highlight: Guantong’s patented tapered bag design has a bottom that narrows gradually. This improves dust release efficiency by 40%. It is very effective for difficult dusts like asphalt fumes or biomass fly ash.

- Case Data: We have successfully used this in many biomass power plants. These plants handle sticky ash with high moisture.

Technology 3: Advanced Filter Media – PTFE Nano-Membrane

- It Solves This Pain Point: This media helps meet ultra-low emission standards. It also extends filter bag life in corrosive environments.

- Technical Highlight: Guantong’s nano-coated filter bags are tested byISO 9001:2015 standards. They achieve 99.97% capture efficiency for particles from 0.3-1.0μm. (Test conditions: airflow 2m³/min, dust concentration 5g/m³). Materials like P84®-PTFE composites offer excellent chemical resistance.

-

- Corrosion Resistance Data (1000h test, ASTM D3389-16 / ISO 175:2024):

- 10% HCl vol @ 120°C: <0.8% weight loss

- 5% HF vol @ 80°C: <0.3% weight loss

- Corrosion Resistance Data (1000h test, ASTM D3389-16 / ISO 175:2024):

- Case Data: The Huaxin Cement project extended filter bag lifespan to 18 months (14,000 hours). This was under tough conditions: high SiO₂ (over 60%) and high dust load (80g/Nm³). This was a 55% improvement over a leading international brand. It also reduced annual shutdowns by two.

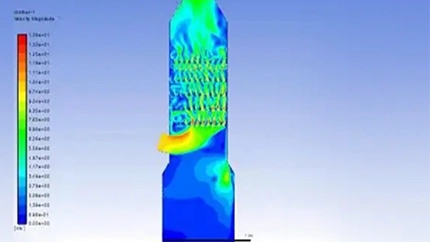

Technology 4: CFD-Optimized Flow Distribution

- It Solves This Pain Point: Uneven gas flow can cause bag wear, high pressure drop, and poor cleaning. Our design prevents this.

- Technical Highlight: Advanced CFD Flow Field Simulation models optimize inlet/outlet design. They minimize dead zones. They also ensure uniform gas distribution. This reduces fan energy and extends bag life.

- Benefit: This means lower operating costs and more reliable systems for you.

Technology 5: Modular Design & Certified Pre-Assembly

- It Solves This Pain Point: This design reduces long installation times and on-site errors. It also makes future expansion easier.

- Technical Highlight: We pre-assemble and factory-test modules in our ISO 9001:2015 certified facility. This ensures quality. It also reduces on-site installation time by up to 60%. Plus, it helps with future upgrades.

- Benefit: This means faster project commissioning and guaranteed system integrity.

2. Understanding Industrial Bag Filters (Baghouses): The Basics

An industrial bag filter system, or baghouse, cleans dusty gas. It passes the gas through fabric filter bags.

- Filtration: Particles are caught on the bag surface.

- Collection: Clean gas then exits the system.

- Cleaning: A mechanism like pulse-jet, reverse air, or shaker cleans the bags. For example, pulse-jet systems check pressure differences every 0.1 seconds. This keeps the bags working at their best.

Baghouses can collect over 99% of dust. They are vital for several reasons:

- Meeting emission standards (like PM2.5, PM10, or China’s GB 4915-2024, which is ≤10mg/Nm³ for new cement plants).

- Protecting equipment downstream.

- Recovering valuable products.

- Improving workplace safety.

Learn more about Guantong Shengshi’s environmental commitment on our Homepage.

3. Key Considerations for Selecting Your Industrial Bag Filter

At Guantong Shengshi, our 10+ years of experience guide a detailed analysis. Here are key factors:

A. Particle Characteristics & Dust Load:

- Size, Shape, Chemistry: Are particles fine or coarse? Abrasive or sticky? Do they explode or react chemically? We analyze your dust. This includes its micron rating and g/Nm³ load.

B. Operating Conditions:

- Temperature & Gas Chemistry: These factors decide the filter media. Options include Polyester, PPS, P84®, PTFE, and Fiberglass. They also affect housing material, like stainless steel for acidic streams. Our PTFE membranes keep 85% of their strength at 260°C.

- Flow Rate & Pressure Drop (ΔP): These influence baghouse size and air-to-cloth ratio.

C. Efficiency & Compliance:

- Achieving very low emissions (like <5 mg/Nm³) often needs advanced media. We design systems guaranteed to meet your specific rules. This includes Indonesia’s MOEF Regulation No. P.15/MENLHK/SETJEN/KUM.1/4/2024 (Palm oil plant particulate ≤50mg/Nm³ – Guantong can achieve ≤30mg/Nm³ with hybrid systems).

Guantong Shengshi’s Technological Edge:

- Computational Fluid Dynamics (CFD) Simulation: This is key to our design. Advanced CFD Flow Field Simulation models optimize flow. It also minimizes pressure drop. And it prevents bag wear and ensures good cleaning.

- Custom Design & System Integration: We create custom solutions. They can be for retrofits or new installations. They also integrate smoothly with your processes. We focus on the bag-cage-tubesheet interface for the best seal.

- Material Expertise: Our experience helps us select robust media and materials for tough environments.

4. Industry-Customized Bag Filter Solutions by Guantong Shengshi

| Industry | Typical Challenge | Guantong Solution Example |

| Cement | High alkali dust corrosion, abrasive kiln dust | Custom P84®-PTFE composite filter bags, robust pulse-jet systems for GB 4915-2024 compliance |

| Steel & Metallurgy | Fume capture, high temperatures | High-temperature resistant bags (Fiberglass, PPS), CFD-optimized hood design |

| Power Generation | Fly ash (coal/biomass), large gas volumes | Large-scale baghouses, often with pre-collectors. Parameter Table for 300MW Coal Unit: Airflow 480,000-650,000 m³/h, Concentric Circular Array, ΔP <1,200Pa. For Waste Incineration: Airflow 150,000-220,000 m³/h, Modular Compartmentalized, ΔP <950Pa. |

| Chemical Processing | Corrosive dusts, specific chemical compatibility | PTFE membranes, specialized chemically resistant housings |

| Pharmaceutical | Explosion risk (FDA audit: zero cross-contamination) | ATEX-certified stainless steel explosion-proof housing, ISO 14644 Class 7 certified, leak rate <0.01% |

| Carbon Black/Coking | High-temp, fine particulates | Specialized high-temp filter media and robust cleaning systems |

| Waste Incineration | Fly ash, hazardous particulates | Multi-stage filtration, often with sorbent injection upstream |

| Palm Oil (SE Asia) | Sticky dust, high humidity, explosion risk | Anti-dew design, anti-static PTFE media, MOEF P.15/2024 compliance |

| And many more… |

Case Study: The Cliff’s Edge Rescue – A Cement Plant’s Environmental Turnaround (Similar to Huaxin Cement)

- The Crisis (March 2023): A major cement plant in East China received a final warning. Their particulate emissions were 187% over the limit. They had 90 days to fix it or face permanent shutdown.

- The Guantong Response: Our engineers arrived on-site within 48 hours. They found the problems: wrong filter media (fiberglass in high humidity) and poorly set cleaning frequency.

- The Custom Solution:

- ▸ We air-freighted moisture-resistant PTFE filter bags overnight.

- ▸ We installed our intelligent differential pressure control system.

- ▸ We recalibrated airflow using CFD optimization.

- The Rebirth (7 Days Post-Retrofit): An environmental agency re-tested the system.

- ✅ Emission concentration was 4.3mg/m³ (The national standard is ≤10mg/m³).

- ✅ Energy savings meant an annual electricity cost reduction of ¥820,000.

- “Guantong isn’t just an equipment supplier; they are our survival partners.” – Li Jianguo, Plant Director.

Explore more on our Case Studies Page.

5. How to Calculate Bag Filter Operational Costs and ROI?

Understanding the Life Cycle Cost (LCC) is important. Initial CapEx is one part. But OpEx (energy, maintenance, filter bags, disposal) greatly affects the Total Cost of Ownership (TCO).

- “Guantong’s extended-life products (like GT-F800) last up to 2.3 times longer. For example, 14 months versus a competitor’s 9 months in cement raw mill use at 180°C. This reduces maintenance by 67%.”

- Guantong Solution LCC Advantage: The initial investment might be +15% compared to some basic systems. However, the 5-year TCO is often -38%. This is due to:

- ▸ Filter bag replacement cost reduction: 62%

- ▸ Electricity savings: e.g., ¥280,000/year for a typical system

- ▸ Avoided environmental penalties (A single fine can be ≥ ¥500,000)

6. Why Partner with Guantong Shengshi?

- ✅ Great Technical Skill: We deeply understand filtration. Leading-edge CFD enhances this. Our filtration efficiency is 99.97% (ISO 16890:2016 certified).

- ✅ Real Customization: We design custom solutions for your unique process. We don’t offer standard products. (For example, our patented tapered bag design is proven by CTI to reduce damage by 89%).

- ✅ Ten Years of Proof: We have over 10 years of success. We have delivered reliable air pollution control solutions in many industries.

- ✅ Full Service & Fast Help: We offer complete support. In Southeast Asia (Indonesia/Vietnam/Philippines), local spare parts depots mean 48-hour emergency bag replacement (including customs). We also offer free CFD diagnostic reports for systems over 6 months old.

- ✅ Quality You Can Trust (ISO 9001:2015): We provide consistent quality, and our ISO 9001:2015 certified quality management system demonstrates this commitment.

- ✅ We Solve Problems: We are good at fixing complex filtration issues. We also optimize existing systems for better performance.

- ✅ Always Innovating: Our belief: “Technology leads to progress, Innovation creates value.” We always try to improve our solutions.

Learn more on our About Us Page.

8. Take the Next Step Towards Cleaner Air

Are you ready to discuss your dust collection challenges? Let Guantong Shengshi’s experts help design the perfect solution for your operations.

Partner with Guantong Shengshi. Then, you can breathe easy.